V12 Diesel Aircraft Engine - Founded in 2006, Skye Avionics has extensive experience in avionics and wiring installation. But a recent project has given them more of a thrill at work than ever before: a new engine for the De Havilland Canada DHC-2 Beaver.

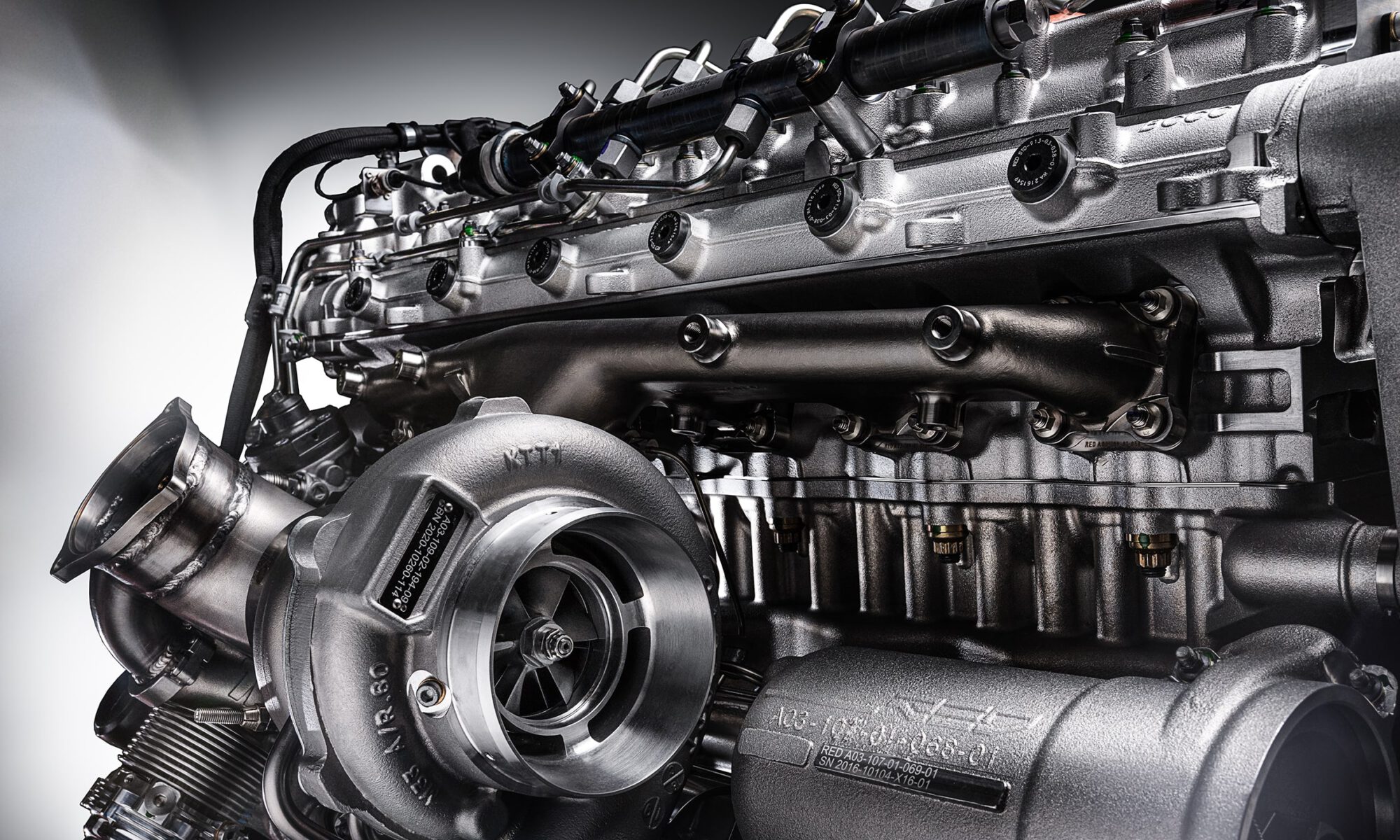

In partnership with Germany's RED Aircraft GmbH, Sealand Aviation contracted the Skye team to handle the electrical and avionics aspects of the project.

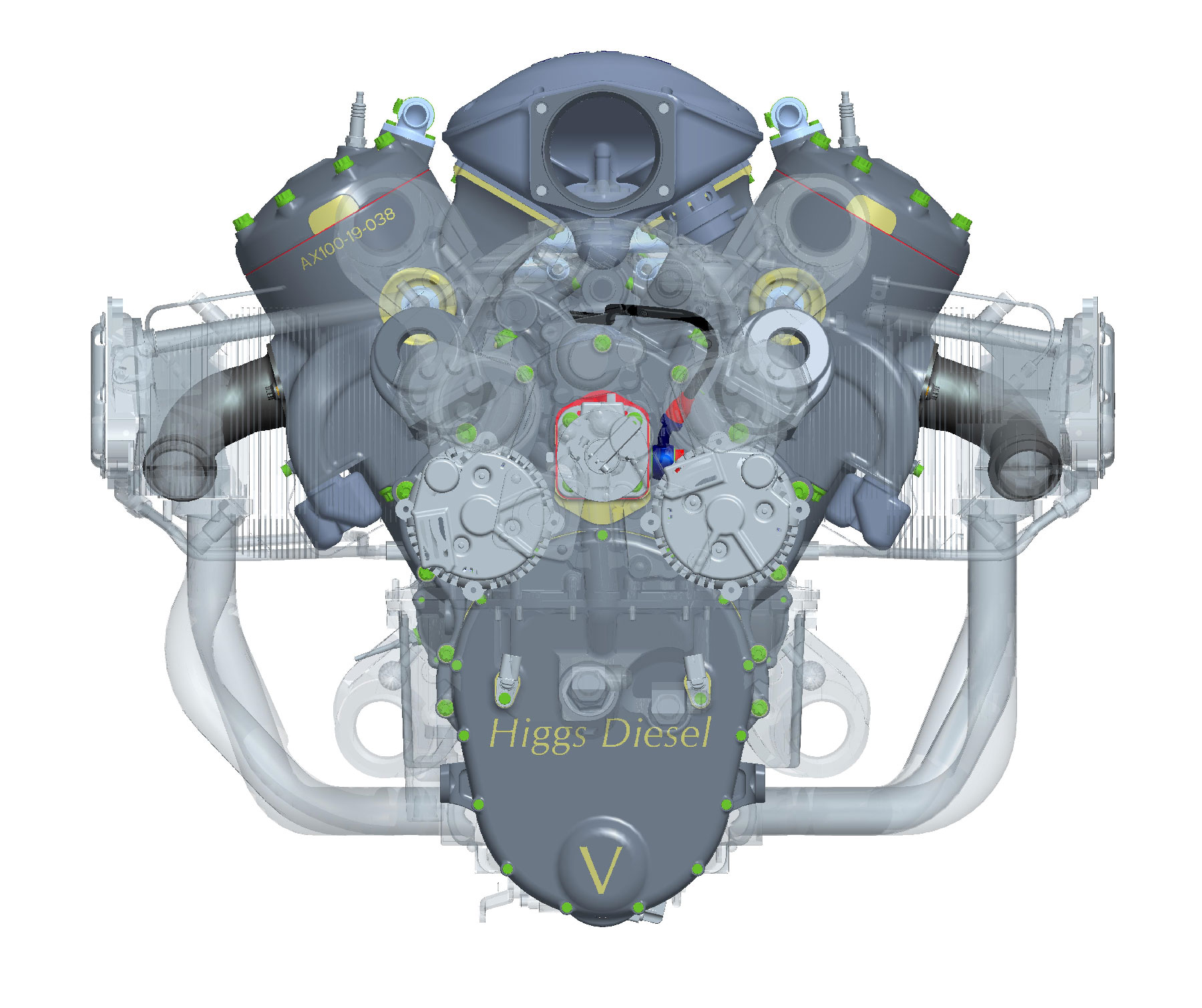

V12 Diesel Aircraft Engine

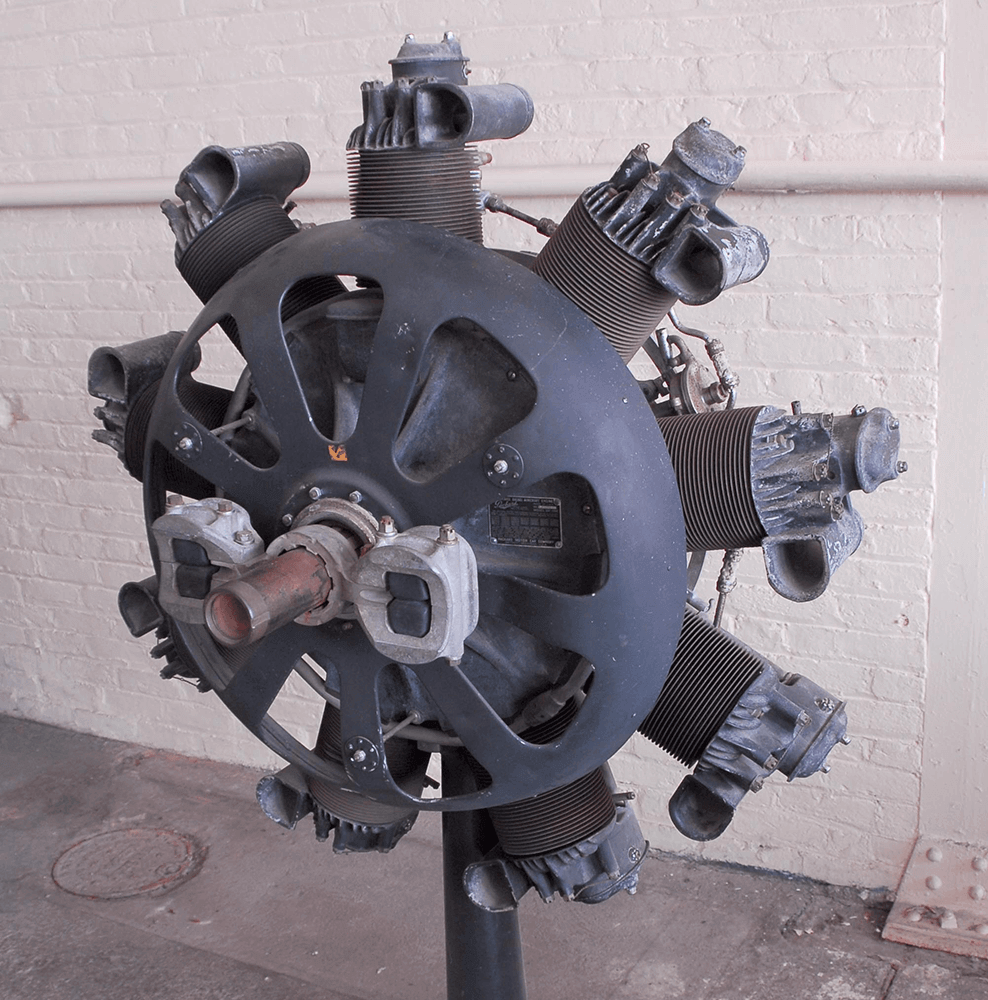

The single-engine, high-wing, propeller-driven DHC-2 Beaver was first produced in the 1940s and 1950s. According to Sealand, the Beaver proved to be virtually irreplaceable, with the company calling it the "best duster".

First In Flight

The Sealand Aviation DHC-2 Beaver (C-GSBA) (pictured) will soon become the first in the world to be powered by the RED A03 engine. Skye Avionics's photo

The special Beaver (C-GSBA) selected by Sealand for modification will soon become "the first in the world" to be equipped with the RED engine, an all-electric 12-cylinder compression-ignition (diesel) engine. aluminum, producing 550 horsepower. A03 - described as the most powerful aircraft piston engine ever produced. The engine has now been type-certified by the European Union Aviation Safety Agency (EASA) and the Federal Aviation Administration (FAA).

Sealand has "taken care" of DHC Beavers for over 40 years and has a number of Supplemental Certificates (STCs) including Alaska door and cockpit extension kits. The Campbell River, British Columbia-based company entered into a 50/50 partnership with RED Aircraft to assemble a team to develop engine modifications.

The RED A03 engine runs on jet fuel, burns 50 percent less fuel than similar turboprop engines, and features a two-cylinder reserve-bank concept for safety.

Economical, Ecological, Fast Private Diesel Jet: Celera 500l

Sealand Aviation President Bill Alder said: "A project like this is always on our radar. The Pratt & Whitney R-985 [Wasp Junior] is a great engine, but it was built in those days. 30 years old and it's time to replace it.Beaver is an amazing plane.Do you know how many 70 year old trucks are in service every day?

"None of this happened overnight," Alder continued. "Twenty years ago, Sealand designed the V8 engine for the Beaver, but we stopped the project. Ten years ago, we worked with Trace Engines in Texas. As part of the Trace project, an engine A 600hp V8 was installed in the Beaver. Trace eventually installed it in the Beaver.STC was obtained but the project was never completed before the financial crisis ended.”

Discussions between Sealand and RED Aircraft about the latest Beaver engine project "started a few years ago, when we were working on the Trace engine," Alder said. "As with any large project, money was an issue. However, borrowing money and working with RED Aircraft pushed the project forward."

Sealand Aviation contracted with Skye Avionics to help install the RED A03 engine with warning panels designed by Skye. Skye Avionics's photo

Moscow Region, Russia

However, the National Research Council of Canada "did not provide any support," according to Alder. "They wanted us to go all-electric right away."

Sealand hopes to eventually have the infrastructure to support electric planes. But this gap is "the answer because this engine will significantly reduce the environmental footprint."

Ryan Evans, president of Skye Avionics, said he was delighted to choose Skye to help install Sealand and RED. In sharing the ups and downs of this once-in-a-lifetime experience, Evans admits that redesigning the electrical system was the biggest obstacle.

"Another obstacle we faced was on the flight deck," he added. “[We're] used airframes and airframes from the 1940s, then used engines driven by FADEC, added four lithium batteries, and then put it all back together. So trying to do it all is a challenge."

Ase 650 Saga

As an approved aerospace manufacturing and certification body, Skye manufactures wiring and components for OEM installations.

It took Skye seven days to redo Project Beaver's electrical system. “We are developing the power distribution center and all the parts of the power system,” explains Evans. "We can manufacture stands so that if someone wants to finish the modification, it's just plug and play."

The 550 hp, all-aluminum, compression-ignition, 12-cylinder RED A03 engine has been described as the most powerful jet piston engine ever produced. Skye Avionics's photo

Skye also designed a warning sign. “The FADEC system requires several warning lights. Instead of using bulky conventional warning lights, Skye Avionics is designing and manufacturing LED warning signs,” says Evans.

Peugeot Unveils V12 Hdi Dpfs Diesel Motor

With over 20 years of avionics experience, Evans is an electrical project manager. He strategically selected his team, including project leader Josh Roy, who installed the avionics and electrical systems; Brendan Loken, responsible for avionics installation, programming and testing; and Caitlin Evans, responsible for avionics and electrical system projects.

In addition to the Beaver alarm panel, Skye also features ICS cables, video splitters, mobile radio interfaces, and Bluetooth interface technologies.

The modification of the DHC-2 is almost complete. The first engine work took place in early February and the first flight is expected soon, pending flight approval from Transport Canada. There will be some flight tests, such as wheels, floats and skateboards, as well as hot and cold testing. STC approval is expected by the end of 2022.

RED and Sealand have a Facebook group dedicated to providing updates on the project called DHC-2 De Havilland Beaver RED A03 and Skye has shared the progress on her YouTube channel.

For Sale: A Rebuilt A 28 Liter Allison V12 Aircraft Engine

Click the button below to email our team and we will contact you as soon as possible. Andy Higgs, a British citizen who has lived in Japan for the past 32 years, is on a mission to bring a new engine to the aviation industry. , in the form of a jet that ignites the letter A "two-stroke piston". The three-year FAA certification pilot program will begin late next year.

"We built several engines to validate the technology and they all worked extremely well. There were no technical demonstration stops and I signed off on the final design a few months ago. "

According to Higgs, president, chief executive officer and sole owner of Tokyo-based AC Corporation, the engine is offered in a variety of variants, including a 1,000-horsepower V12 (incl. gear box) weighs 665 lb/302 kg; 302 lb/137 kg four-cylinder with 350 hp (again, including a gearbox that drops 5,300 crankshaft rpm to 2,300 rpm); and the 1.5-liter V4 weighs just 103 pounds/47 kg and makes 120 horsepower. The commercial business model for the V12 is "to compete with the 580 to 1200 hp PT6 market as an alternative to Cessna Caravans. The killer for caravan operators is fuel costs. our engine compared to PT6 in terms of capacity, power, etc. will increase operating space by 40 percent." For smiles and tech demonstrations, the 1,000-hp V12 is destined to power at least one NXT engine in the Sport class at Renault someday.

Higgs explains the technology: "It's different from a conventional two-stroke engine in that we can separate the crankcases with conventional four-stroke lubricants. We can use simple bearings and don't need them. mixing oil with fuel We can separate the two-stroke concepts from the crankshaft and the lubricating mechanism.

Allison V 1710

"The cylinder is slightly longer than a conventional two-stroke cylinder, but much shorter than a four-stroke. We divided the cylinder into two separate bore diameters: the smaller hole diameter is for the top hole, is for our working piston; underneath we have the pump piston.The piston looks like a helmet.As it passes through the bore, the air (and nothing else) ) is sucked into the compression chamber.As it moves up, it pushes the air out of the compression chamber and pushes it to the next piston's "working piston" stage.As the piston moves further and close the exhaust port we put the injectors directly into the cylinder and burn clean That's why you're limited to about 10,000 feet on a typical two-stroke engine. Also, the pressure drops a lot (and the delta drops a lot). you won't be able to transfer fuel.

"This engine is designed for a critical altitude of 38,000 feet. With a turbocharger, it will go as high as anyone wants. Asking people how to handle the fuel pile means they are looking too tall. We have a way to heat the fuel, so there's no limit on altitude."

The concept of the stepper piston motor dates back to around 1904, says Higgs, “If you want to take a step into the future, look back and

V12 aircraft engine for sale, v12 diesel engine for sale, isuzu v12 diesel engine, v12 diesel, gemini diesel aircraft engine, cummins v12 diesel engine, aircraft diesel engine, aircraft diesel engine conversion, eps diesel aircraft engine, diesel engine for aircraft, continental diesel aircraft engine, aircraft diesel engine manufacturers

0 Comments